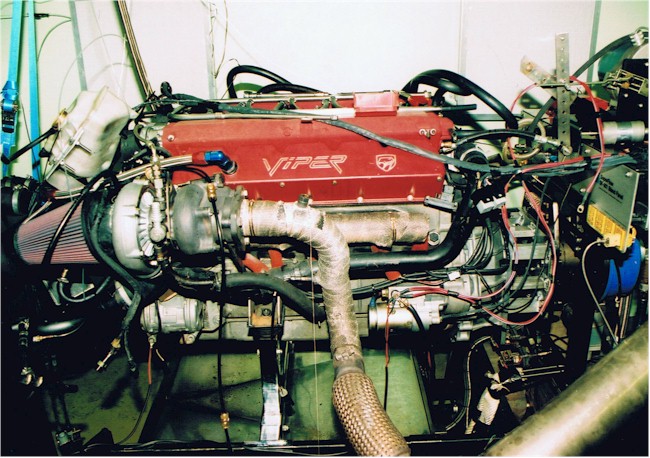

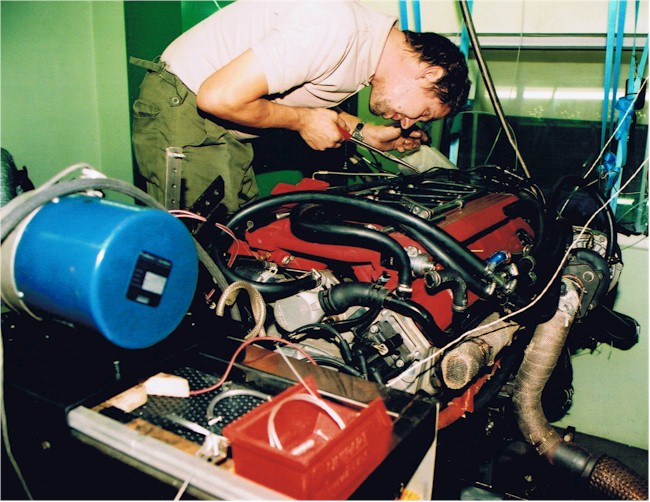

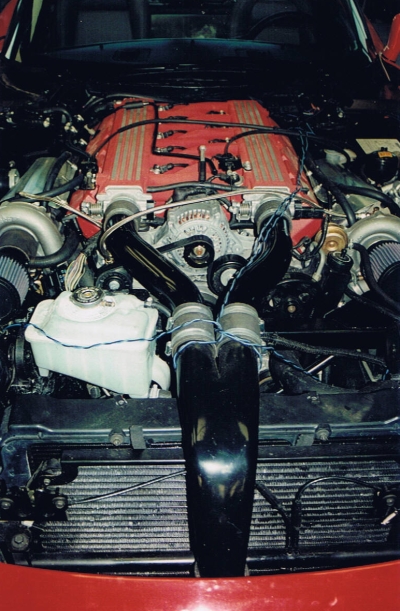

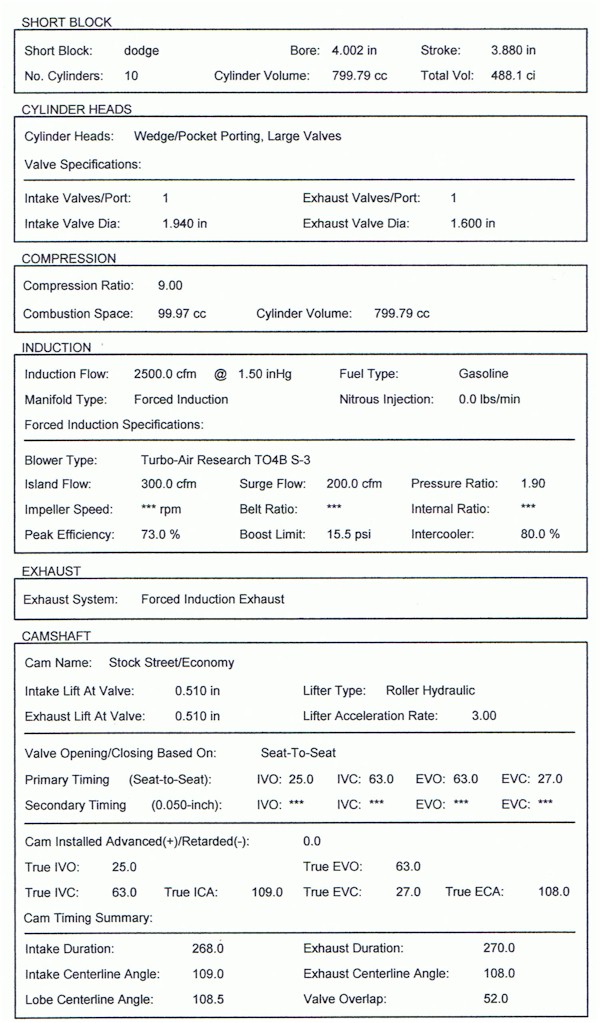

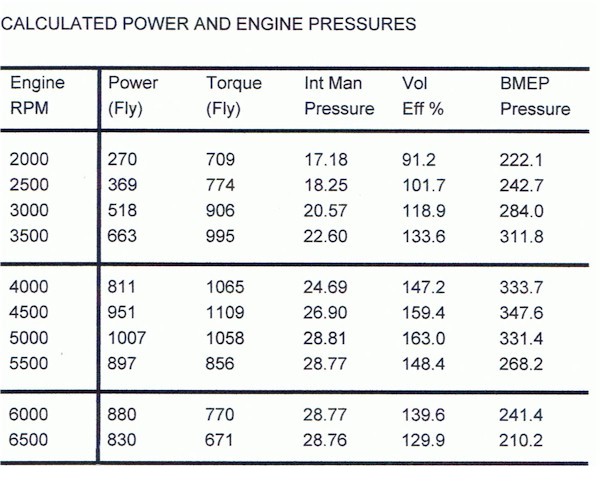

Twin to4 modified turbos running variable boost control upto 20 psi of boost were fitted for starters, with turbo manifolds and exhaust made up for us by Maniflow in Salisbury . We then asked Mcloud clutches to manufacture a twin 10.5 inch custom clutch for our project, for which we supplied them with new flywheel to develop this as it had to support 1000 bhp and 1000 ft lbs of torque. Ours was the first clutch of this type made and they've since been selling them for vipers for 14 years ( Ha! Where's our royalties?)